Explain the Purpose of Different Elements of Gating System

8 c Describe the different elements in the information technology Explain how the IT. With use of gating systems several castings in a single mold possible.

Elements Of Gating System Metal Casting

It may be made out of core sand or it may be cut in cope portion of the sand mold.

. Breaking the mold and getting the casting. To get enough metal into the mold cavity before the metal starts to solidify 3. The key is to design a system that promotes directional solidification.

Broadly gating designs can be classified into three categories namely- i vertical gating ii bottom gating and iii horizontal gating. 42 Describe the objectives of gating systems in any casting. The functions of a gating system are.

To avoid erosion of mould cavity. In vertical gating the liquid metal is poured vertically to fill the mould with atmospheric pressure at the base. In casting process gating system plays an important role to produce a high quality casting.

This is used most widely. Is the fraction solid. Explain riser functions in detail.

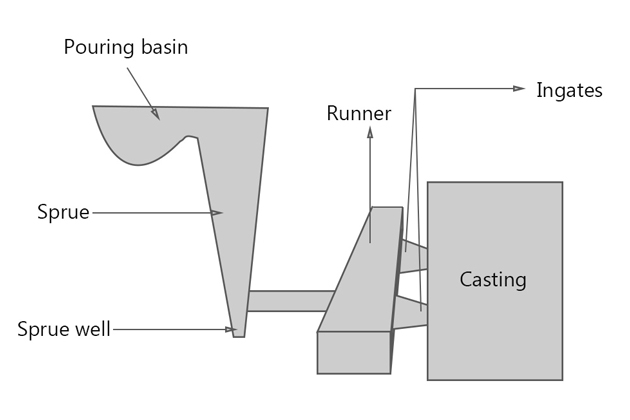

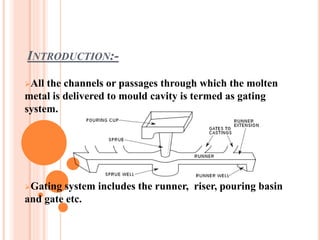

Consisting of a pouring cup and tunnels or gates to the mold its used to funnel the molten mold into the mold cavity. The gating design for a ceramic mould is quite different from that normally used for a permeable sand mould. To provide continuous uniform feed of molten metal with little turbulence as possible to the mould cavity.

45 Explain why the sprue should be tapered. It provides a large range of the complete behavior of the casting during solidification. Elements of Gating System.

Basically a gating system functions during. Article shared by. A gating system controls mould filling process.

Top Gating System. To supply the casting with liquid metal at best location achieve proper directional solidification and optimum feeding. 44 Give the sketch of a design of a pouring basin with an arrangement for trapping slag.

Casting simulation utilizes finite element procedures depending upon the complexity of the problem. Casting iron in a sand mold. Vertical Gating System.

Sometimes the gating system will be cut by hand or in more adept manufacturing procedures the gating system will be incorporated into the pattern along with the part. Write short note on shell molding. To minimize turbulence to avoid trapping gasses into the mold 2.

This is applied in tall castings were high-pressure sand mold shell mold and die-casting processes are done. Explain various casting defects in brief. A poorly designed gating system results in casting defects.

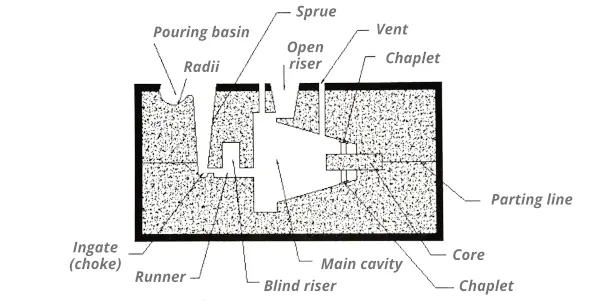

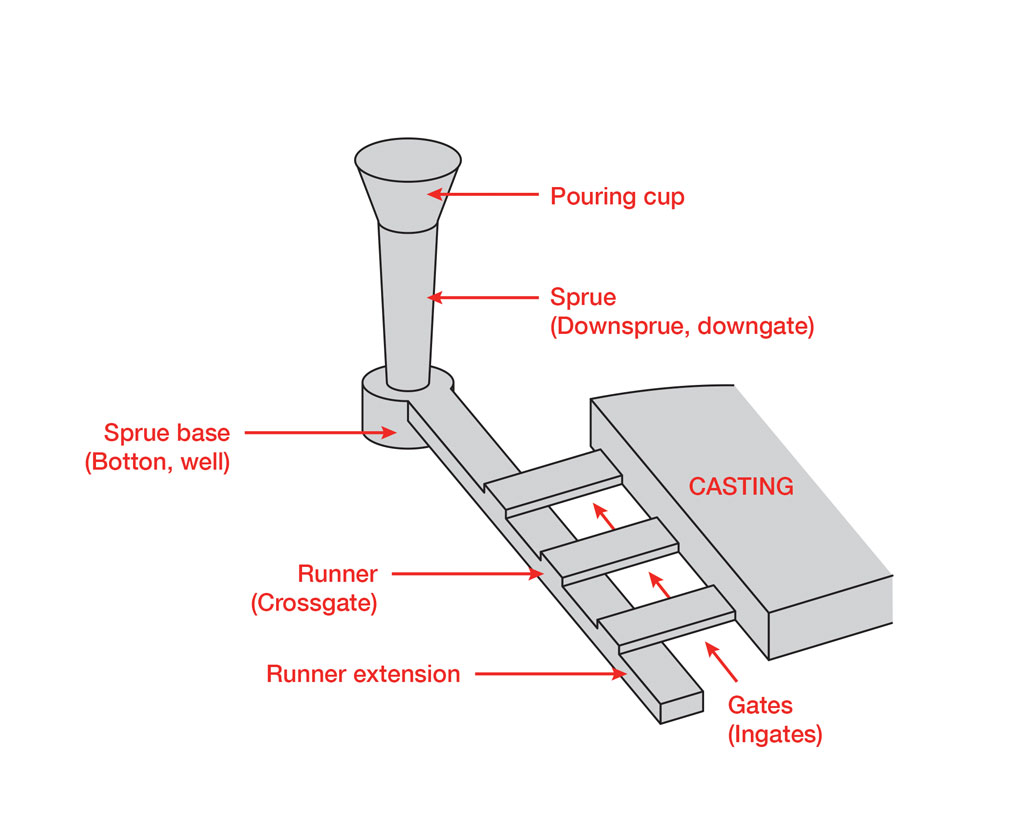

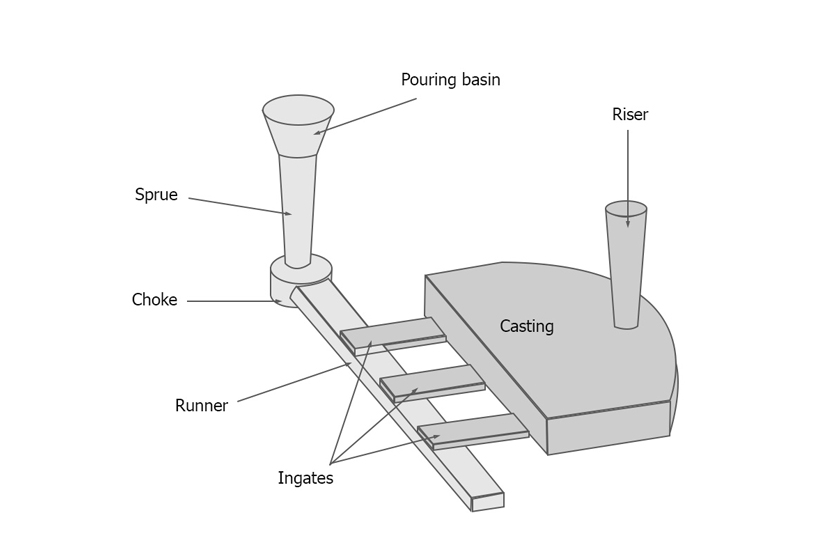

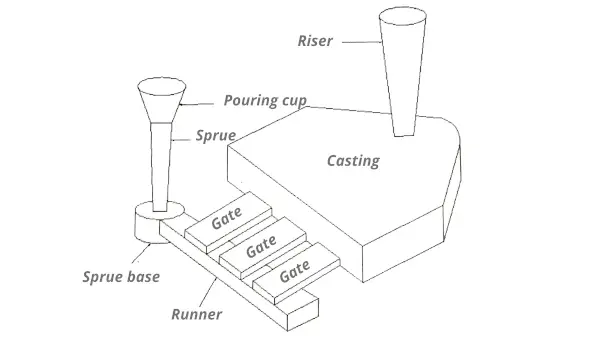

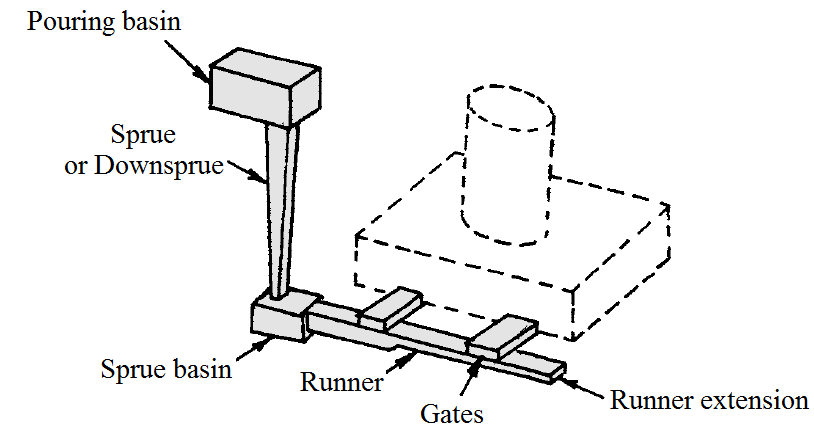

Pouring the molten metal in the mold cavity. Fill the mould cavity completely before the metal starts to solidify. The main elements needed for the gating system are as follows.

The main function of gating system is to lead molten metal from ladle to the casting cavity ensuring smooth uniform and complete filling. Explain any two types of patterns in detail. A gating system should be able to do the following.

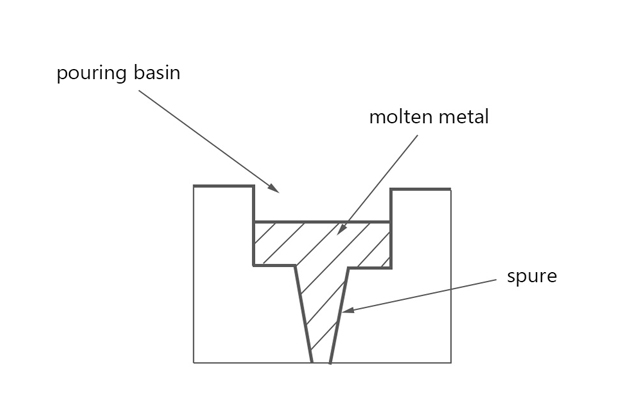

By controlling gas velocity and angle of intercept different shapes and sizes of powders can be produced. The metal is poured into the mold through a hollow channel called a sprue. CHARACTERISTICS OF GATING SYSTEM o The purpose of gating system is to deliver the molten metal to mold.

Making a proper gating system in the mold. Write principle and working of induction furnace. Draw part gating system showing different gating elements.

After placing the mold pattern in sand manufacturing companies will set up a gating. S and V are the surface area and volume of the element and f s. An effective gating system should.

The gatingfeeding system initially governs the mold filling operation and guides the molten metal as it flows into the mold filing cavity later while solidification it guides the feeding liquid into this cavity as compensation for the first two stages of alloy. The primary way to control metal casting defects is through good mold design considerations in the creation of the castings mold and gating system. Before making the mold the properties of the molding sand should be checked.

The various elements include. Following are the elements of gating systems. To prevent aspiration of air or mould gases in the liquid metal stream.

To fill the mould. DESIGN OF GATING SYSTEM To fill the mould cavity without breaking the flow of liquid metal and without using very high pouring temperatures. The objective of project is to design and simulate gating and risering system components by using simulation technology to get defect free casting.

Directional solidification in casting manufacture means that the material will solidify in a manner that we plan usually as uniformly as possible with the areas. 12 Main Elements of Hydroelectric Power Plant. To avoid shrinkage 4.

41 What are the various elements that comprise the gating system. The gating system includes all those elements which connect the pouring ladle to the mould. They are used for flat casting which are filled under gravity.

To minimize turbulence and dross formation. In order for this mold to be functional to manufacture a casting in addition to the impression of the part the mold cavity will also need to include a gating system. But unlike sand casting in investment casting the gatingfeeding elements provide dual or combined function of both.

Step 2 Set Up the Gating System. There are different types of molding sands. In metalworking and jewelry making casting is a process in which a liquid metal is delivered into a mold usually by a crucible that contains a negative impression ie a three-dimensional negative image of the intended shape.

A hydroelectric plant consists of a reservoir for storage of water a diversion dam an intake structure for controlling and regulating the flow of water a conduit system to carry the water from the intake to the waterwheel the turbines coupled with generators the draft tube for conveying. The goals for the gating system are 1. Atomized powder is a major source for the powder metallurgy industry.

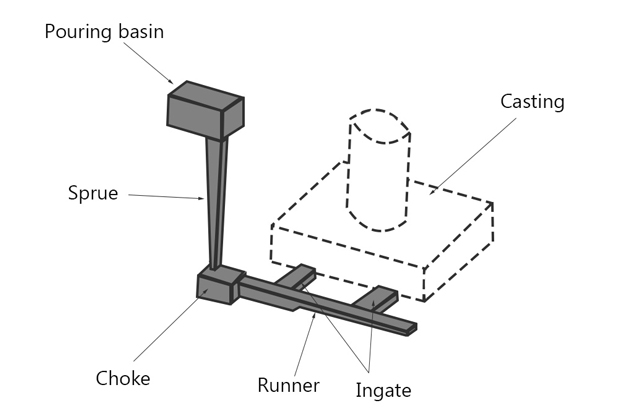

This type is normally applied in ferrous metals sand casting and gravity die-casting of non-ferrous metals. Pouring Basin Sprue Sprue Base Well Runner Runner Extension Gate or Ingate Riser 6. Most casting processes involve the use of a gating system and sand casting is no exception.

Differentiate green and dry molding sand. Pouring Basin or cup Sprue Sprue Base Well Runner Runner Extension In-gate and Riser. Pouring basin or bush.

Establish the best possible temperature gradient in the solidifying casting so that the shrinkage if occurs must be in the gating system not. The gating system is composed of. Permit complete filling of the mold cavity 2.

A Explain with a neat sketch the principle of Resistance spot welding 6 b Show the different elements of robots. 43 What are the functions served by the pouring basin in a sandcasting. Horizontal Gating System.

With diagram show four types of the robots. Pouring basin-It is the conical hollow element or tapered hollow vertical portion of the gating system which helps to feed the molten metal initially through the path of gating system to mold cavity. Cooling the mold to the room temperature.

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Riser And Gating Design Engineers Knowledge

Gating System In Mold Mechtech Guru

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Types Of Gating System In Casting Process Bajrang Engineering

Gating System In Sand Casting 13 Elements You Should Know

Home Safety A Checklist To Print Today Rich Dad Poor Dad Rich Dad Poor Dad Summary Home Safety Checklist

5 Types Of Gating System In Metal Casting Processes Omnidex

Various Parts Of Gating System Download Scientific Diagram

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Gating System Definition Function Types Diagram Marinerspoint

Elements Of Gating System Metal Casting

Gating System In Sand Casting 13 Elements You Should Know

Riser And Gating Design Engineers Knowledge

Types Of Gating System In Casting Process Bajrang Engineering

Comments

Post a Comment